Product製品情報

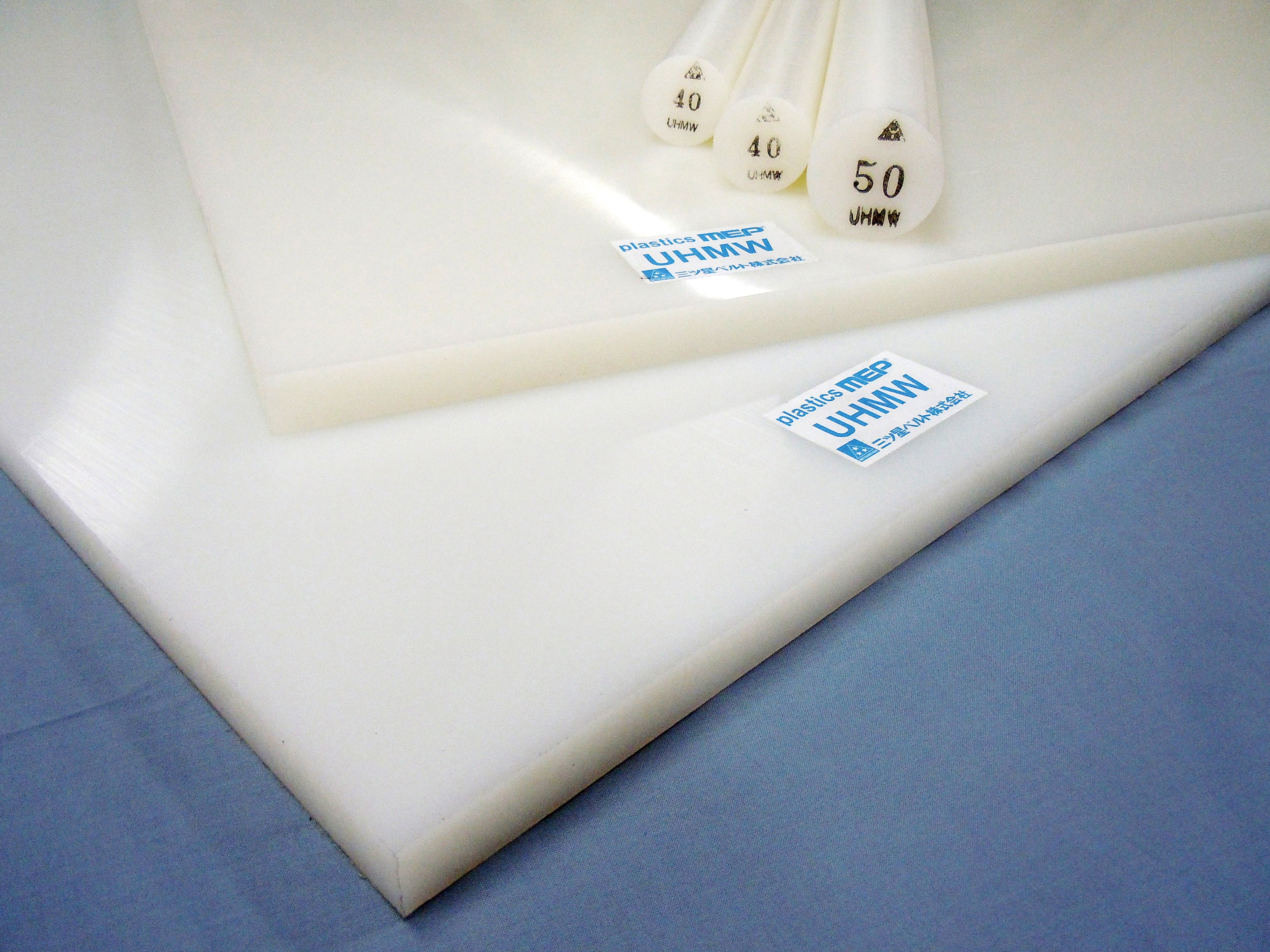

Engineering Plastics

Materials and Processed Products

:By Industries

Crushed Stone and Plant Industry

Summary

In the crushed stone industry, which is indispensable for infrastructure development, materials with excellent impact and abrasion resistance are required to achieve stable production under harsh environments. Our engineering plastics offer superior impact and abrasion resistance, thereby extending equipment life and improving replacement cycles.

Required Specifications

Impact Resistance

Excellent impact resistance prevents equipment damage and ensures stable production in the processing of gravel of various sizes.

Abrasion Resistance

It has excellent abrasion resistance, especially in gravel applications, and can be used as a protective material for metal hoppers and shooters.

Non-Adhesiveness

Excellent non-adhesiveness reduces the risk of line stagnation by suppressing the bridging phenomenon in sediment handling.

Self Lubricity

The self-lubricating material improves the frequency of equipment maintenance and enables lower cost operation.

Engineering Plastic Materials for the Crushed Stone and Plant Industry

Adoption Examples

Dehydrator

Sliding grade material and self-lubricating properties reduces the frequency of equipment maintenance and improves running costs.

Hopper liner material

Ultra-high molecular weight polyethylene with excellent non-adhesion and abrasion resistance protects the equipment body and suppresses bridging phenomena.

_eng.png)